March 7, 2026

Advancing

Sustainable Global

Electrification

Our global recycling platform is creating sustainable supply chain solutions for critical metals

About Us

Long term, affordable availability of battery materials is crucial to ensuring a green transition to global electrification. Shifting to a more sustainable tomorrow will require that our precious, essential and finite resources are utilized responsibly.

ACE Green Recycling is an innovative battery recycling technology platform offering sustainable end-of-life solutions. It has deployed modular, Zero Scope 1 Carbon emissions-free recycling plants for Lead batteries and Lithium (NMC & LFP) used in various industries including electronics, automotive and energy storage. Collaborating across the battery ecosystem, ACE aims to create localized circular solutions to retain critical battery materials within countries generating battery wastes.

ACE Difference

We use proprietary Scope 1 emissions-free technologies to recycle multiple chemistries of Lead and Lithium batteries.

100% electrified, hydrometallurgical recycling process

Modular solutions with low capital expenditure

Processes compliant with strict regulations in the EU and the USA

Technologies to recycle Lead batteries, LFP, NMC & LTO

Industry leading recoveries of Lead, Lithium, Graphite & NMC salts

R&D to recover metals from mining and smelting wastes

Technology

ACE’s lithium battery recycling technology has been assessed and validated by global consulting firm Arthur D Little.

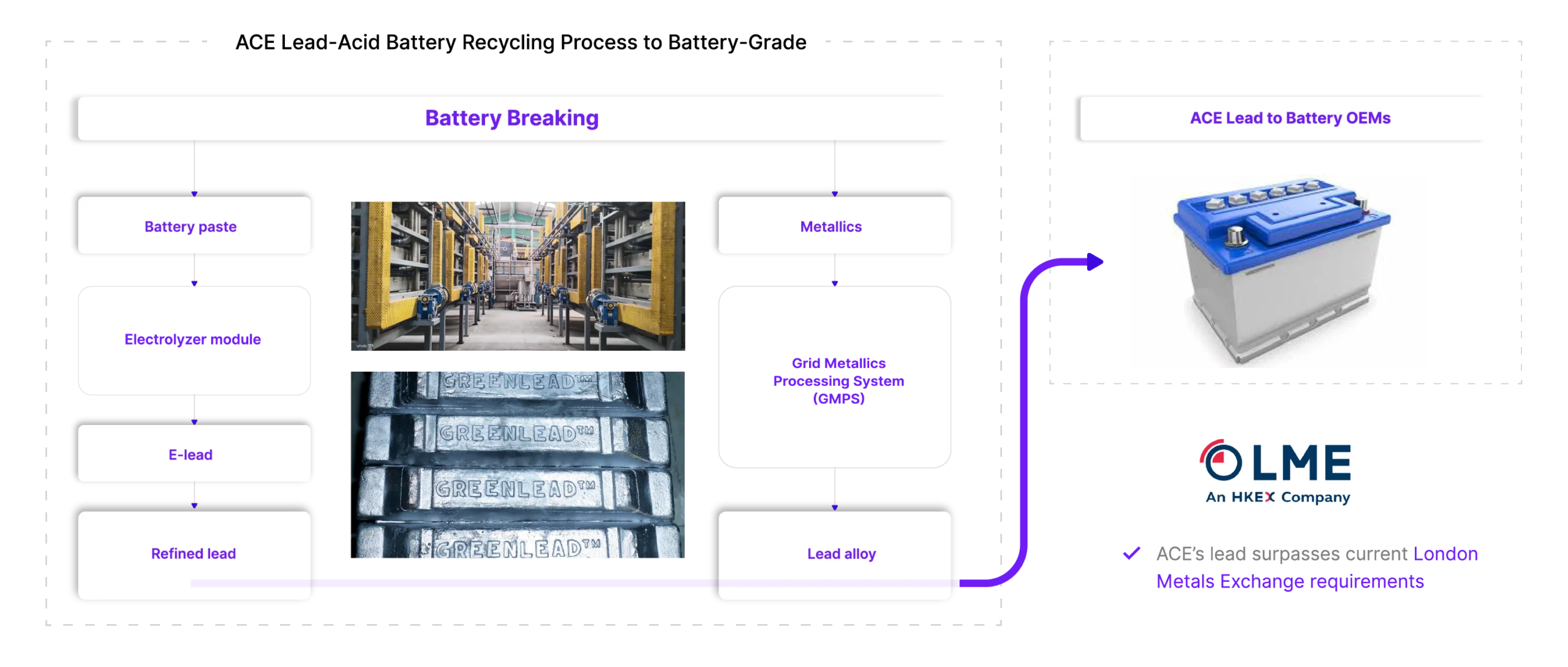

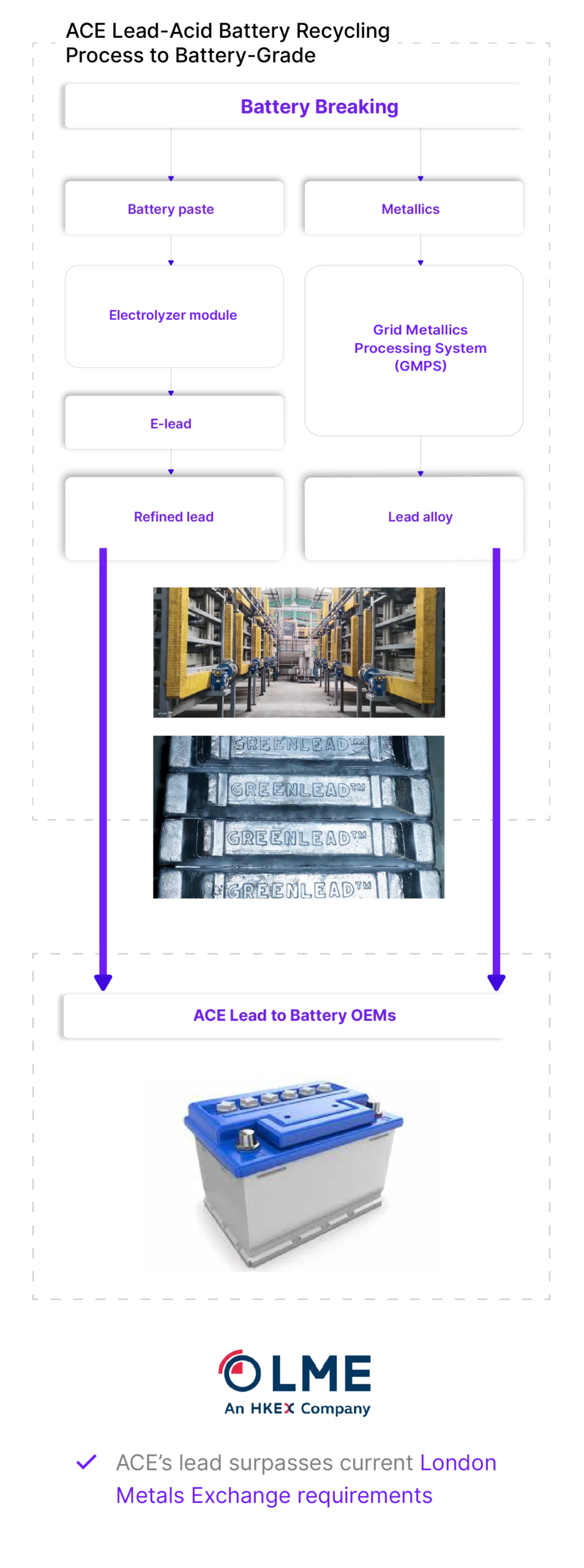

ACE’s GREENLEAD® process can produce battery grade lead with a clean process.

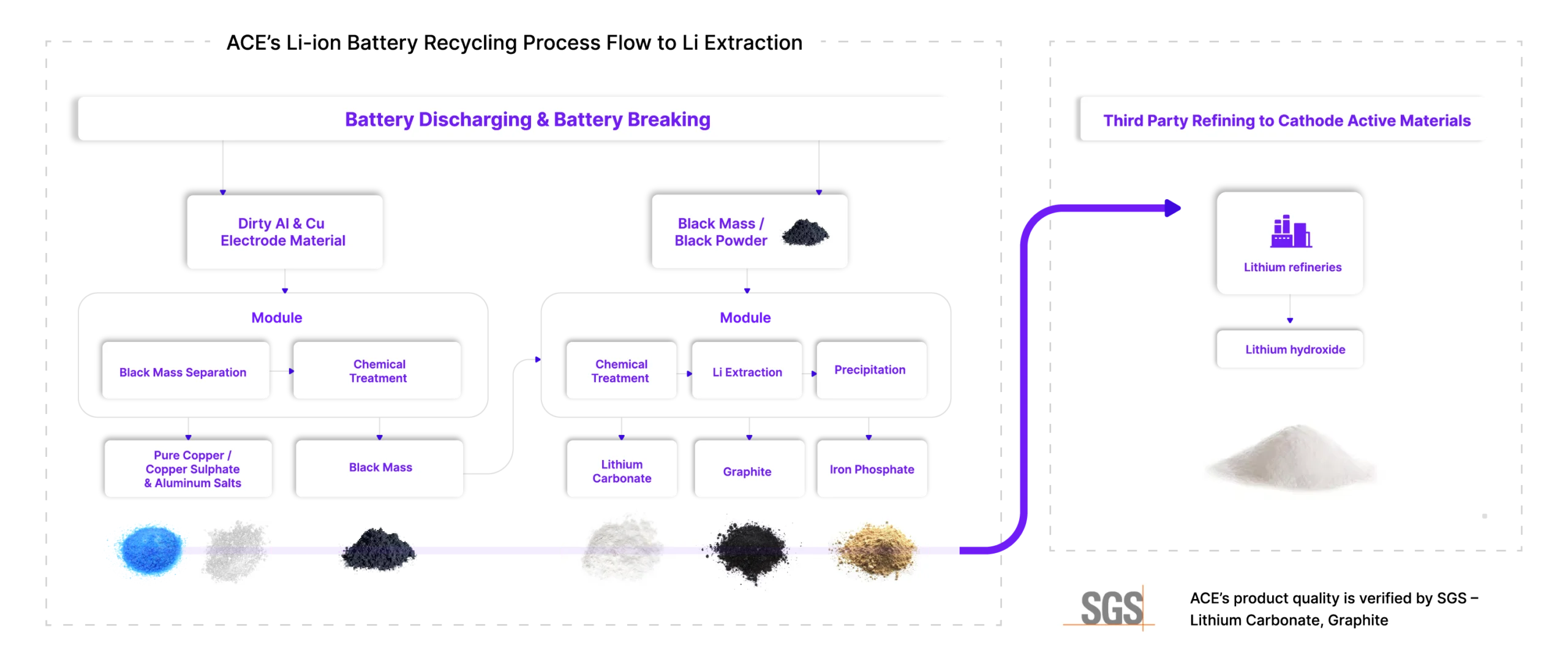

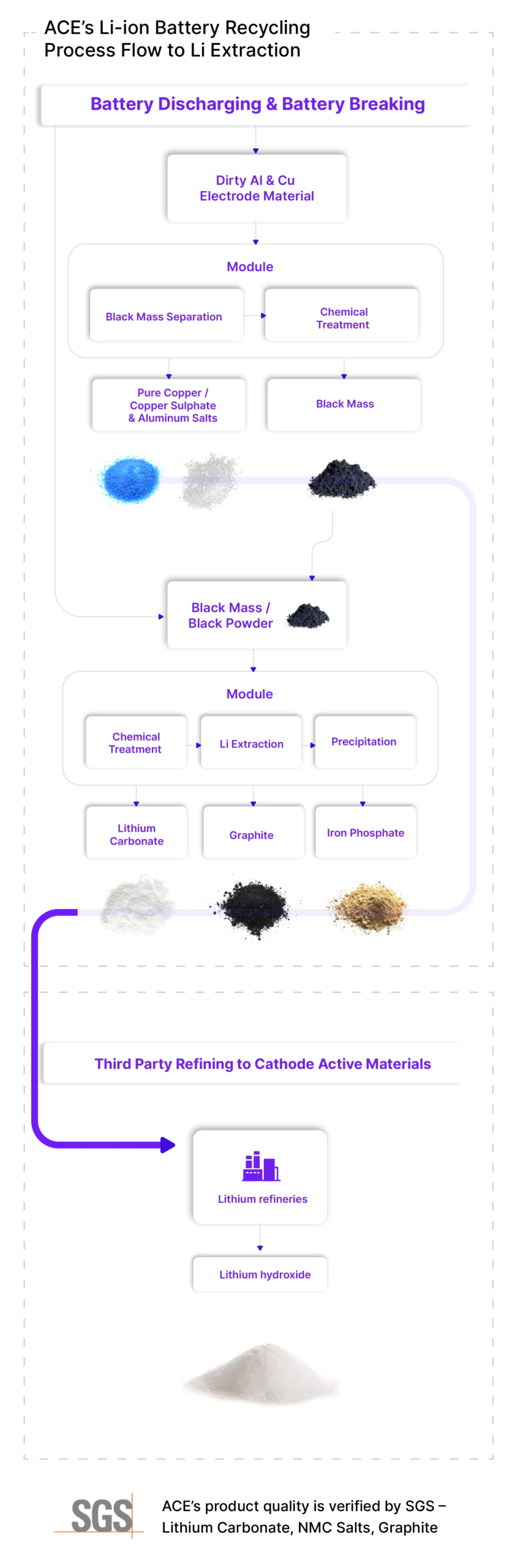

ACE’s LithiumFirst™ process can extract valuable materials from LFP batteries.

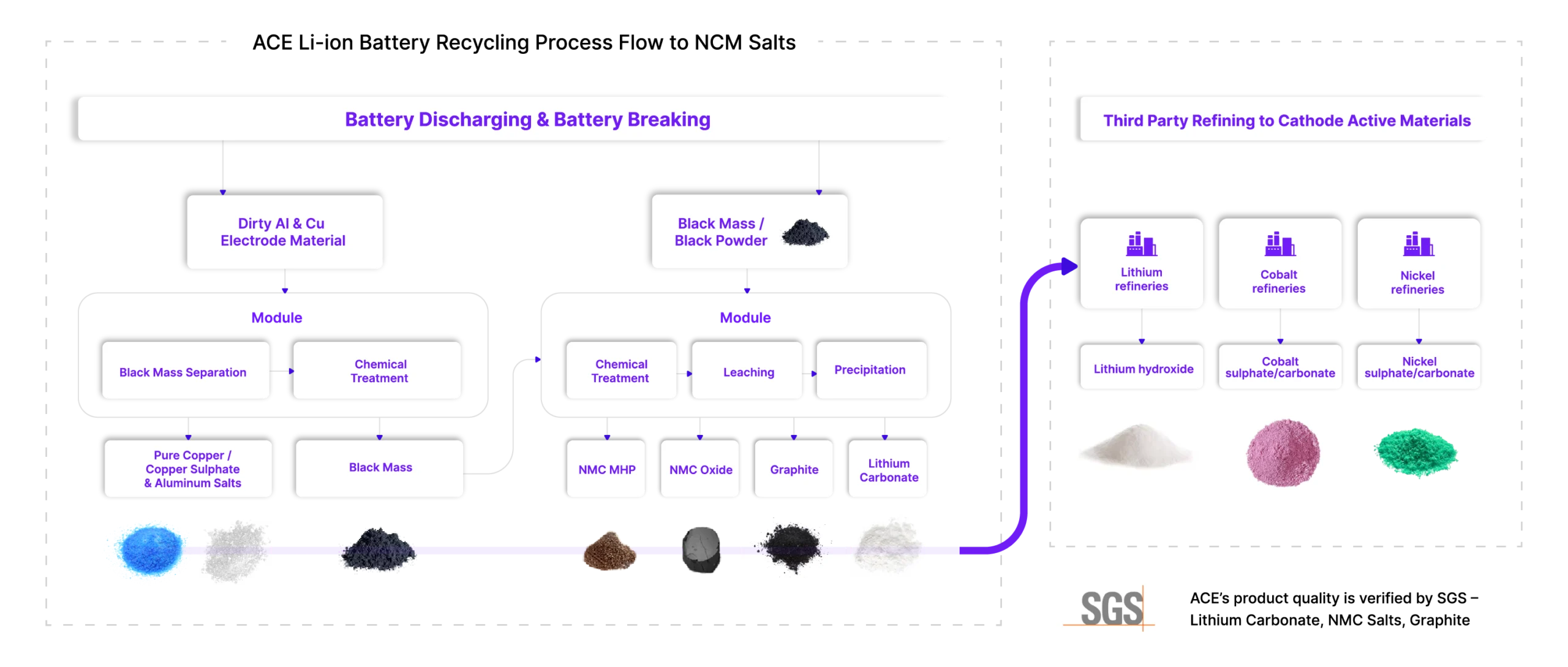

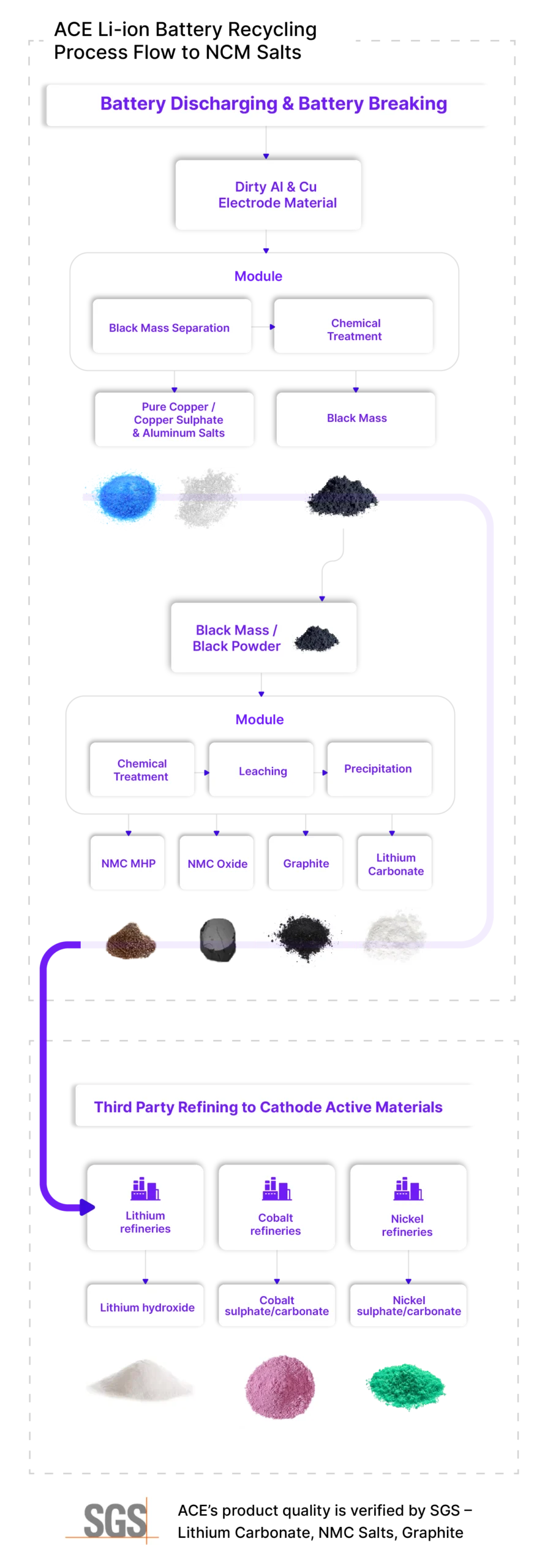

ACE’s LithiumFirst™ process can extract valuable materials from NMC batteries.

ACE Materials

ACE uses a diverse metal waste feed to produce a variety of reusable battery materials

INPUT

GREENLEAD®

OUTPUT

LITHIUM CARBONATE

NMC MHP

NMC Oxide

Graphite

COPPER SALTS

Plastics

Flexible technology design allows to manufacture precursors and various metal salts (Sulfates/ Carbonates/ Hydroxides) and their combinations as per customer requirements.

Precursor

COBALT SALTS

Nickel Salts

Sustainable Recycling

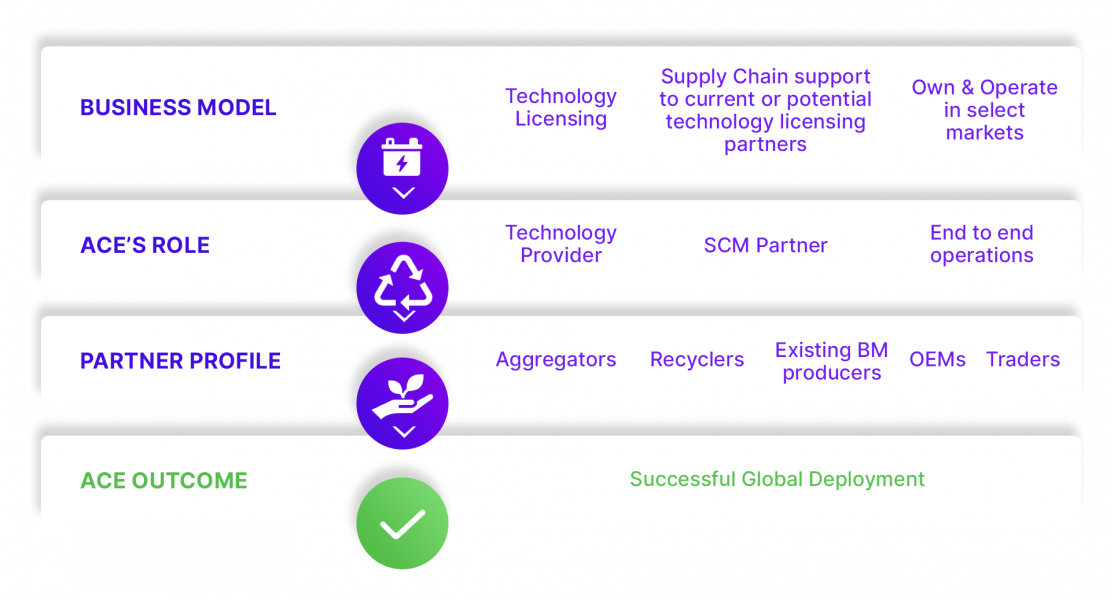

ACE collaborates with partners across the battery value chain, providing innovative technology solutions to establish clean and sustainable recycling facilities. In the United States, we are focused on establishing our own advanced recycling operations to build domestic battery material resilience. Internationally, we engage with existing recyclers, licensing our advanced technology to enhance legacy facilities in response to growing market demands and regulatory requirements. We also work alongside various stakeholders in the ecosystem to establish new facilities through strategic partnerships. Our typical partners include battery aggregators, black mass producers, battery OEMs, recyclers, refineries, auto companies, second-life players, and commodity trading companies. Beyond our U.S. operations, ACE spearheads greenfield projects worldwide through joint ventures with global players, fostering localized capabilities and bolstering domestic battery material resilience in key markets.

WORLDWIDE

Locations

Planned Facilities

Existing Facilities

Offices

Current & Planned Facilities

We currently operate lead and lithium plants in India and Taiwan. Our near-term expansion plans include lead and lithium plants in the US, Europe, and Asia Pacific.

CURRENT FACILITIES

2023

INDIA

Lithium

2024

TAIWAN

Lead

PLANNED FACILITIES

2026

USA

Lead

2026

ARMENIA

Lead & Lithium

2026

AUSTRALIA

Lead

2026

THAILAND

Lead

Our Team

Recent News